About KARL DEUTSCH

A success story for more than 70 years

The company KARL DEUTSCH was founded in 1949 and is currently managed by the third generation. It deals with the development and manufacture of equipment for non-destructive material testing (NDT).

Mobile testing and measuring devices, stationary testing systems, sensors and chemical crack detection equipment are manufactured at two sites in Wuppertal by 130 motivated employees. Another 20 employees in foreign offices and a worldwide subsidiary network support the export business, which accounts for more than 50 % of sales.

Our customers are mainly from the metal producing and processing industry. Steelworks, suppliers to the automotive industry such as forges and foundries and manufacturers of ball bearings are important customers. Typical inspection tasks comprise weld seam inspection and the detection of casting cavities with ultrasound. Surface crack testing on forged parts is carried out using magnetic particles and the dye penetrant method. Safety parts for rail transport and aviation are also examined by means of NDT. Portable measuring instruments for wall and coating thickness measurement as well as for field strength and crack depth measurement complete the product range.

The company is rooted in Wuppertal in the region Bergisches Land. The deep connection to the city and area is actively lived. This includes extensive commitment to numerous projects that make the city more liveable. Examples are the “Nordbahntrasse” bike track and the Junior Uni.

Flexible and customer-oriented

- Our mobile testing devices, stationary testing systems, sensors and chemical crack detection equipment are developed and manufactured in two plants in Wuppertal.

- Specialists in the fields of UT, MT and PT work daily to further improve our products which have been established for years. Based on close interaction of the individual production areas, we offer our customers tailor-made technical solutions.

- The concentration of all important production steps from purchasing, warehousing and production to sales and service enables short distances and flexible optimization.

- Certification and testing of portable devices, for instance in the context of quality assurance requirements, is carried out quickly and easily in-house and usually takes not more than 4 days. Even with complicated tests, it takes a maximum of about 10 days before the device is ready for use again.

- Customer service is a top priority for us: Nearly all technical questions about our products are answered by our application technology laboratory. The proximity to production and development enables us to provide the greatest possible customer orientation.

Production

The company headquarters in Wuppertal consists of two sites, which are about 600 m apart.

Works 1 in Wuppertal: At this location, you’ll find the administration, development and a part of the production of KARL DEUTSCH. The buildings were erected in 1967 and 1972.

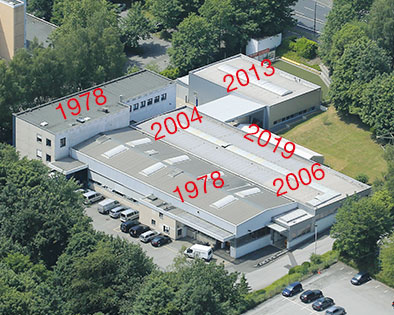

Aerial view of Works 2, also in Wuppertal: The annual figures mark the continuous expansion of our production facility for UT systems and MT devices/systems.

Made in Germany: In our Works 1 we produce all KARL DEUTSCH portable instruments, sensors and chemical testing media.

In the assembly hall for ultrasonic testing systems in Works 2 there is sufficient space even for the construction of large systems.

The KARL DEUTSCH systems for magnetic particle crack detection and penetrant testing are also produced in Works 2.

Technical Application Support

Several application technology laboratories form the heart of KARL DEUTSCH. Well-trained employees, often with NDT level 3 certificates, look forward to support our customers with their complex testing tasks.

A laboratory in Works 1 with three employees is primarily dedicated to topics such as portable testing devices, ultrasonics and phased arrays.

In our technical centre we have an MT system with various types of magnetization, as well as a semi-automatic PT system. All common test methods can be carried out on the customer’s component under practical conditions. Properties of testing media are examined in the chemistry laboratory. An extensive range of analysis methods allows for a comprehensive evaluation of the products.

The ultrasonic system laboratory in Works 2 has a 12 m long roller table and a testing system for rods and tubes (diameter up to 100 mm, testing speed up to 2 m/s). Either conventional ultrasonic electronics or phased array electronics are used. A second, mobile testing system is available for rotary testing of component diameters above 80 mm.

On-site Service

As we manufacture almost all products with a high added value in the Wuppertal factories, it’s a matter of course that we always have important spare parts in stock. Mobile testing devices are usually checked and, if necessary, repaired by our inspection and repair facility within five working days. On request, the processing time can be reduced even further, and rental equipment can also be used so that our customers are always ready for testing.

Worldwide installation of the systems is carried out by our highly qualified service engineers. For the after-sales service we have established a worldwide network of sales partners and their service staff, who are available for our customers on-site. By now, most of the testing systems have a remote diagnosis facility. This enables us to solve many of the minor problems quickly and avoiding red tape.

Our service engineers are on duty worldwide.