Ultrasonic Testing System ECHOGRAPH-KNPS Billet Testing

Product Description

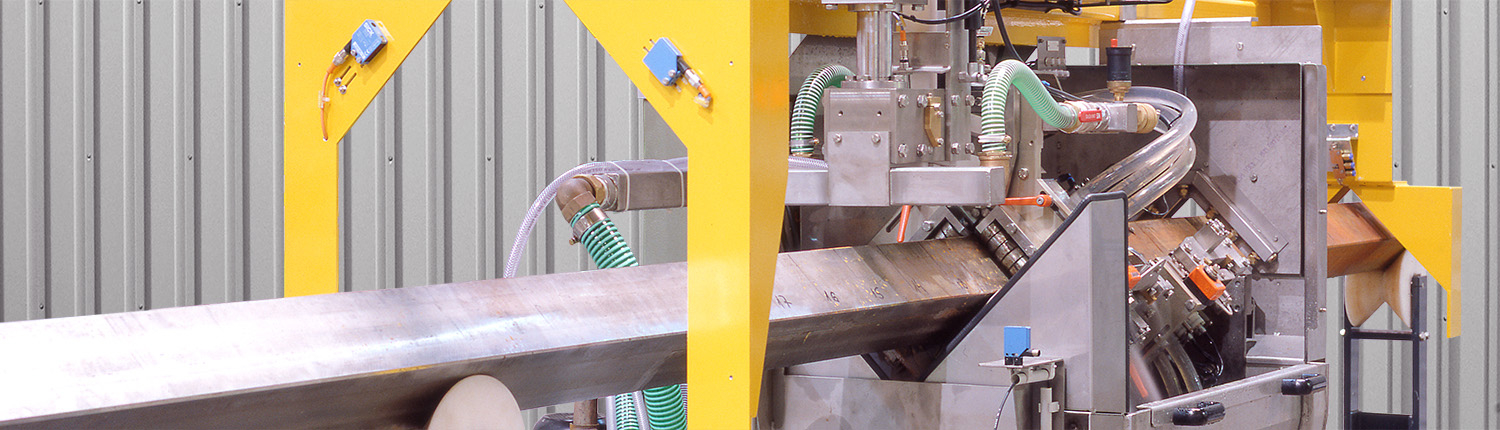

Nowadays, round and square billets (typical cross sections approx. 100 mm – 300 mm) usually are produced in continuous casting technique and are often inspected with ultrasound directly afterwards. The KNPS probe holders can also reliably scan slightly curved and twisted billets thanks to their gimbal-mounted suspension.

An outstanding feature of the ECHOGRAPH-KNPS testing system is the particularly reliable ultrasonic coupling using a water jet. For sound beam coupling, distance variations from probe to the billet surface in the range of millimeters are not critical. Water jets also permit low-wear coupling and fast changeover to different profile dimensions coming with a high coverage of the billet cross-section.

When testing square billets, 28 probes (divided between four probe carriers) are used to insonificate vertically into the billets. For the inspection of round billets, the inspection mechanics are converted and nine probes are used. Three probes cover the core area and six further probes work with angle-beam insonification for the near-surface area.

Key Facts

- Fast billet inspection for diameters 100 mm – 300 mm

- Linear billet conveyance (0.5 m/s – 1 m/s)

- 9 – 28 conventional probes

- Coupling via water jets (squirter technique)

- Fast changeover

- Compensation of the straightness tolerances by cardanic suspension of the probe holders

- Probe holders work in positioning mode (lowering or raising per billet)

Further Information

Our comprehensive brochure:

Things to know and accessories: