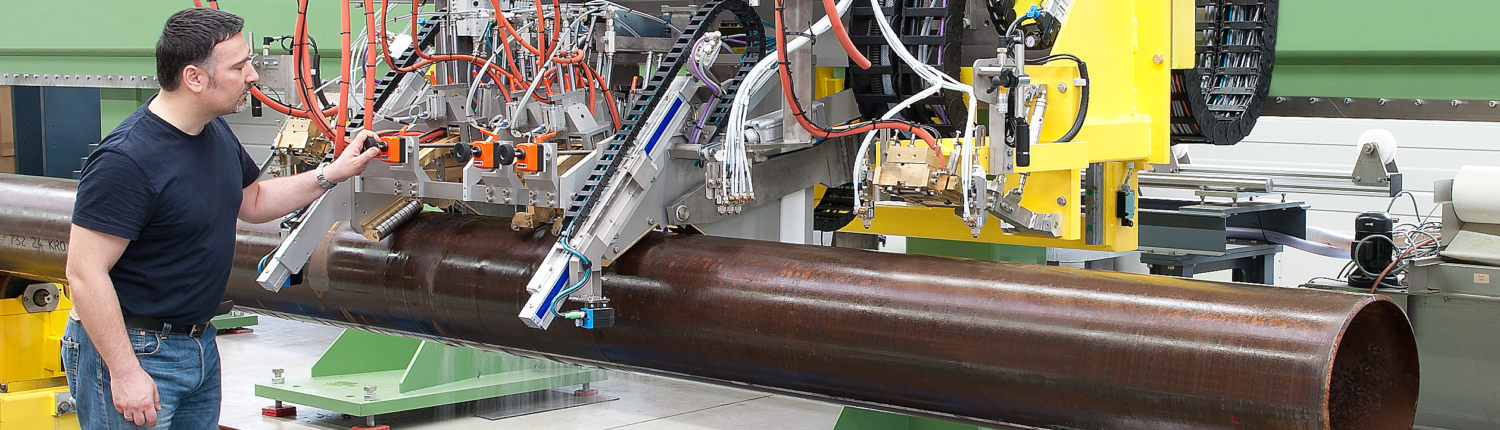

Ultrasonic Testing System ECHOGRAPH-SNHF for RF-Welded (ERW) Pipes

Product Description

With the production of RF-tubes, ultrasonic testing is often used in several places. Directly after welding with a radio-frequency coil, the still hot weld seam is inspected (online inspection on the endless tube). The proven water jet coupling prevents overheating of the probes. Online testing is used for monitoring of the production process at an early stage. Longitudinal defects are detected by angle-beam scanning, usually with four probes. Often internal scraping of the pipe weld seam is also monitored by an additional oscillating vertical probe.

During the further procedure of pipe manufacturing, the endless pipe is sawn and the tubes are subjected to additional production steps. Eventually, the pipe is inspected in another ultrasonic testing stage (offline weld seam inspection). This is usually done with a high-throughput inspection portal or inspection bridge. The examination of the tube body is either performed as a strip test before welding or integrated into the offline test.

Key Facts

- Testing of longitudinally welded RF-tubes

- Typical pipe diameters range from 80 mm to 630 mm (various mechanical sizes)

- Online inspection of the endless tube and offline inspection of the finished tube

- Longitudinal flaw inspection with angle beam insonification, additional inspection tasks depending on specification (e.g. scraping inspection, laminations in the heat-affected zone, in the pipe body and at the pipe end)

Further Information

Our comprehensive brochure:

Things to know and accessories: