Accessories for Coating Thickness Measurement

Calibration Foils and Test Blocks

Checking and calibrating coating thickness gauges

Coating thickness gauges can be checked easily and reliably calibrated with high-quality reference blocks and calibration foils. Depending on the application and measuring range, ferromagnetic (Fe) and non-ferromagnetic (NFe) reference blocks of different sizes and a selection of suitable calibration foil sets are available. For special precision foil sets, the thickness tolerances are reduced even further. Upon request, calibration foils can be supplied with individual quality test certificates.

Reference Blocks

- Reference Block Fe

(order no.: 2815.001) - Reference Block NFe

(order no.: 2815.003) - Reference Block Fe, large

(order no.: 2815.002)

Calibration Foils (recommended standard sets and blocks)

- Calibration Foil Set

measuring range 0 mm – 300 µm, 2 pcs

(order no.: 2715.992) - Calibration Foil Set

measuring range 0 mm – 1250 µm, 6 pcs

(order no.: 2715.001) - Calibration Foil Set

measuring range 1250 mm – 4750 µm, 3 pcs

(order no.: 2715.004) - Calibration Foil Set

measuring range 0.5 mm – 12.5 mm, 4 pcs

(order no.: 2715.002) - Precision Calibration Foil Set

measuring range 0 µm – 1250 µm, 6 pcs

(order no.: 2715.003) - Calibration Block, 15 mm thickness

measuring range 12.5 mm – 20 mm

(order no.: 2715.151)

Certificates

- Calibration Foil Certificate, per foil

(order no.: 2799.001)

Positioning Device

Optimized repetition accuracy for microprobes

Due to their design, microprobes are particularly suitable for measuring coating thicknesses on small objects, in bore holes or on curved surfaces. For comparative serial measurements, the probe needs to be placed on the same location with the same probe orientation. The positioning device will help to achieve these requirements. The placement of the probe, which is inserted into a wire-controlled guidance, is pneumatically damped. The result: Amazing repetition accuracy even on complicated workpiece surfaces.

Positioning Device, for all microprobes

(order no.: 2820.002)

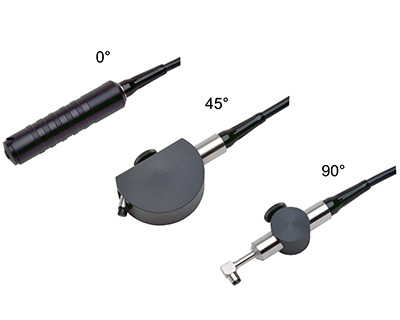

Positioning Aids

Mechanical aids to stabilize the microprobe

These simple positioning aids ensure that errors due to tilted or twisted probes are avoided during manual measurements.

Positioning aids for microprobes

- Positioning Aid for Microprobe 0°

(order no.: 2998.001) - Positioning Aid for Microprobe 45°

(order no.: 2998.002) - Positioning Aid for Microprobe 90°

(order no.: 2998.003)

Tube Measuring Support

Measuring the coating of tubes

For the measurement of tube coatings KARL DEUTSCH offers a special tube measuring support equipped with a special probe.

Special Measuring Support for Tube Measurement

(order no.: 2820.999)

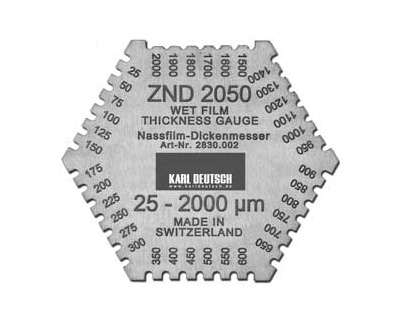

Wet Film Thickness Gauge

Measuring comb for immersion in the liquid film

Wet film thickness gauges are used to determine a wet film thickness (liquid film thickness). The measurements provide an approximate indication of the thickness of a liquid layer. The measuring method is described in the EN ISO 2808 standard. Measuring ranges: 25 µm to 150 µm, 175 µm to 300 µm, 350 µm to 600 µm, 650 µm to 900 µm, 950 µm to 1400 µm and 1500 µm to 2000 µm

Wet Film Gauge (6 sides), stainless steel

25 µm – 2000 µm (order no.: 2830.002)