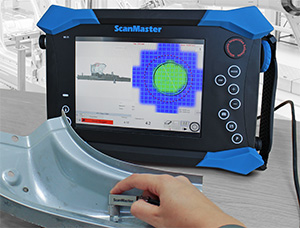

Phased Array Spot Weld Inspector ScanMaster UT/X

Product Description

The inspection of spot welds with the ScanMaster UT/X, which is based on phased array technology, enables direct measurement of the diameter of the weld lens, the welded area and the residual wall thickness of the lens. In addition, statistical evaluation algorithms of the individual A-scans of all elements are used.

The arrangement of the elements in a matrix allows for a complete inspection of weld spots up to a diameter of 9 mm with a single probe. If necessary, conventional probes can also be included in an inspection plan if the PA probe is too large due to the component geometry. In this case, the conventional evaluation algorithms are used again.

The PA probe can be used both with a flexible water delay path and with a fixed rigid delay path, and can thus be adapted to the weld spot geometry.

Key Facts

- Integrated PA-system based on the MANTIS device

- Automatic Go / No-Go decision making and classification of the spot weld quality

- Only one phased array probe for all spot diameters (up to 9 mm)

- Virtually an unlimited number of test setups, C-scans and A-scans can be stored

- Use of well-proven evaluation algorithms

- Support of 2, 3 and 4 plate combinations

- Network connection for data exchange (SpotWeld Connect)

- External data management (UltraSPIS)

- Generation of test reports

Versions

Spot Weld Inspector ScanMaster UT/X with phased array technology (order no.: 6150.140)

The Spot Weld Inspector ScanMaster UT/X

Further Information

Our comprehensive brochure (in German language, consulting and sales limited to Germany):

Things to know and accessories: