ECHOGRAPH 1170: Multichannel Testing Electronics – The Perfect Solution for Integrators!

Wuppertal, Germany, December 28, 2020

ECHOGRAPH 1170: Multichannel Testing Electronics – The Perfect Solution for Integrators!

For several years now, the ECHOGRAPH1170 testing electronics has been very successfully established in the NDT market. KARL DEUTSCH’s own testing systems as well as testing systems from integrators are equipped with this compact and price-efficient module.

The fast testing electronics is completely self-sufficient and is controlled via an industrial PC. In the PC, the ultrasonic data are processed to customer’s specifications with the help of the specially developed ECHOVIEW software. Strip charts, C-scans, tables and statistics are available, amongst others. Experienced integrators can also employ their own data software and use the ECHOGRAPH 1170 electronics as an OEM module. Combined inspection systems using several inspection methods (e.g. eddy current and ultrasound with shared data software) have also been successfully implemented.

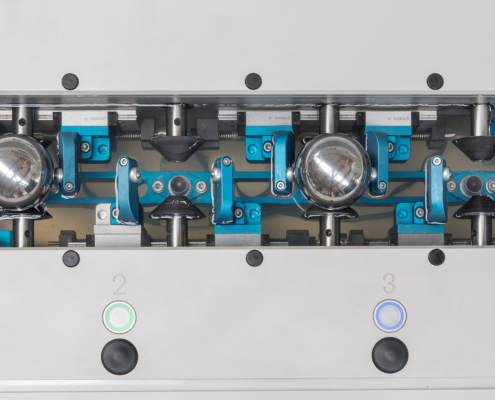

Also for a small number of channels the price-efficient ECHOGRAPH 1170 testing electronics is frequently utilized. Typical examples comprise the inspection of bearing rings, rollers and balls. Several of the world’s leading bearing manufacturers rely on KARL DEUTSCH for these applications! In this context, our worldwide sales and service network is important as well, ensuring short response times for our international customers. One of our many integrators is the company N-DECT, based in Pretzfeld (north of Nuremberg, Germany). Managing Director Jens Geiger was very satisfied with the smooth integration of the testing electronics into his roller inspection mechanisms and with the good support during the projects in Germany, Europe and China. Fast and simple communication between the testing electronics and the electrical control system via suitable interfaces (e.g. TCP/IP, Profinet) is important. In addition, roller inspection has some special features. Since the sound paths change constantly during the probe movement relative to the roller, the ultrasonic parameters (e.g. the monitor gate length) must be dynamically adjusted with reference to the probe position. The test sensitivity is often defined by 0.5 mm FBH and therefore requires particularly lownoise electronics with a large adjustment range for depth compensation (TCG Time-Corrected Gain). The demands on the test mechanics are high as well. The probes need to be guided precisely along the surface of the roller, in the case of spherical rollers via a three-dimensional axis control. This makes the multichannel ECHOGRAPH 1170 testing electronics the perfect tool for a wide range of inspection tasks: Laser-welded gear parts, SEP-1927 immersion tanks for testing of the cleanliness rate, pistons, valves, bearing components and many more.