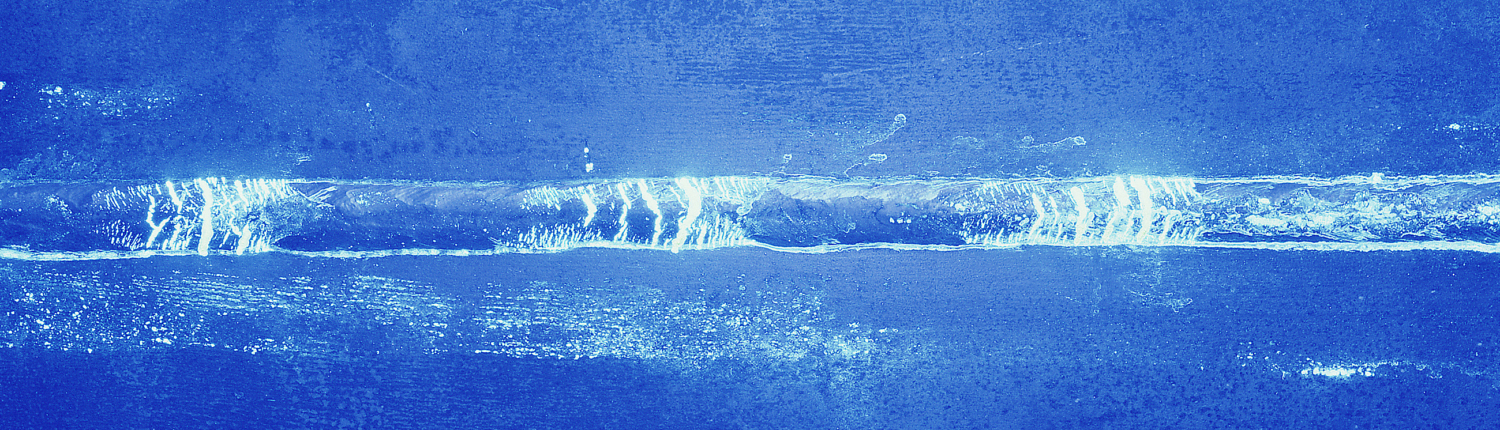

Fluorescent Testing with KD-Check

Penetrant testing using the higher sensitivity of fluorescent testing media is mainly used with serial testing of critical components, for example in the aerospace and automotive industry. When used in stationary systems, a large number of components can be checked reproducibly for finest cracks within a short period of time. In combination with dry developers, which are applied by spraying or electrostatically, the sensitivity during testing is increased even further.

KD-CHECK FWP-1

- Oil-based fluorescent penetrant

- Sensitivity class 2

- Water- and solvent-washable

- Suitable for metals and non-metals (suitability for plastics must be checked beforehand)

- Reduced consumption of inspection media due to low viscosity and optimum dripping properties

- Excellent wetting properties, especially on smooth surfaces

- Very good washability on rough surfaces

- Low background fluorescence

- High test reliability due to high contrast formation

- Low sulphur and halogen content according to DIN EN ISO 3452-2 and ASME Code, Section V, Article 6

- Usable in a temperature range from +10 °C to +50 °C

- Sample tested according to DIN EN ISO 3452-2

Suitable cleaners

Suitable developers

Packages

- 500 ml aerosol can (order no.: 9904.1)

- 1 l can (order no.: 9904.4)

- 5 l canister (order no.: 9904.5)

- 10 l canister (order nor.: 9904.2)

- 25 l canister (order no.: 9904.25)

- Barrel and IBC on request

KD-CHECK FWP-3

- Water-based fluorescent penetrant

- Sensitivity class 0.5

- Water- and solvent-washable

- Suitable for metals and non-metals (suitability for plastics must be checked beforehand)

- Very good wetting properties

- Low background fluorescence

- Very good washability on rough surfaces

- Free from hydrocarbons

- Very good biodegradability according to EN ISO 9888

- Dischargeable in aqueous dilution after approval by local water authority

- Low odour

- Low sulphur and halogen content according to DIN EN ISO 3452-2 and ASME Code, Section V, Article 6

- Usable in a temperature range from +10 °C to +50 °C

- Sample tested according to DIN EN ISO 3452-2

Suitable cleaners

Suitable developers

Packages

- 1 l bottle (order no.: 9914.4)

- 5 l canister (order no.: 9914.5)

- 10 l canister (order no.: 9914.1)

- 25 l canister (order no.: 9914.25)

- Barrel and IBC on request

KD-CHECK FWP-4

- Surfactant-based fluorescent penetrant

- Sensitivity class 1

- Water-washable

- Suitable for metals and non-metals (suitability for plastics must be checked beforehand)

- Very good wetting properties

- Low background fluorescence due to very good washability

- High test reliability due to high contrast formation

- Free from hydrocarbons

- Very good biodegradability according to EN ISO 9888

- Dischargeable in aqueous dilution after approval by local water authority

- Low odour

- Low sulphur and halogen content according to DIN EN ISO 3452-2 and ASME Code, Section V, Article 6

- Usable in a temperature range from +10 °C to +50 °C

- Sample tested according to DIN EN ISO 3452-2

Suitable cleaners

Suitable developers

Packages

- 1 l bottle (order no.: 9915.4)

- 5 l canister (order no.: 9915.5)

- 10 l canister (order no.: 9915.1)

- 25 l canister (order no.: 9915.25)

- Barrel and IBC on request

KD-CHECK FWP-6

- Surfactant-based fluorescent penetrant

- Sensitivity class 2

- Water- and solvent-washable

- Suitable for metals and non-metals (suitability for plastics must be checked beforehand)

- Very good wetting properties

- Low background fluorescence due to very good washability

- High test reliability due to high contrast formation

- Free from hydrocarbons

- Very good biodegradability according to EN ISO 9888

- Dischargeable in aqueous dilution after approval by local water authority

- Low odour

- Low sulphur and halogen content according to DIN EN ISO 3452-2 and ASME Code, Section V, Article 6

- Usable in a temperature range from +10 °C to +50 °C

- Sample tested according to DIN EN ISO 3452-2

Suitable cleaners

Suitable developers

Packages

- 500 ml aerosol can (order no.: 9917.1)

- 1 l bottle (order no.: 9917.4)

- 5 l canister (order no.: 9917.5)

- 10 l canister (order no.: 9917.2)

- 25 l canister (order no.: 9917.25)

- Barrel and IBC on request

KD-CHECK FWP-33

- Fluorescent water-based penetrant

- Sensitivity class 3

- Water- and solvent-washable

- Suitable for metals and non-metals (suitability for plastics must be checked beforehand)

- Very good wetting properties

- Resistant to over-washing

- Reduced test agent consumption due to low viscosity and optimal dripping properties

- Very good biodegradability according to EN ISO 9888

- Dischargeable in aqueous dilution after approval by local water authority

- Low odour

- Low sulphur and halogen content according to DIN EN ISO 3452-2 and ASME Code, Section V, Article 6

- Usable in a temperature range from +10 °C to +50 °C

- Type-tested according to DIN EN ISO 3452-2

Suitable cleaners

Suitable developers

Packages

- 1 l bottle (order no.: 9933.001)

- 5 l canister (order no.: 9933.002)

- 10 l canister (order no.: 9933.003)

- 25 l canister (order no.: 9933.025)

- Barrel and IBC on request

KD-CHECK FP-WB-1

- Fluorescent water-based penetrant

- Sensitivity class 1

- Water- and solvent-washable

- Suitable for metals and non-metals (suitability must be checked beforehand)

- Reduced test agent consumption due to low viscosity and optimal dripping properties

- Very good wetting properties

- Low background due to very good wash-off properties even on rough surfaces

- High test reliability due to strong contrast formation

- Very good biodegradability according to EN ISO 9888

- Dischargeable in aqueous dilution after approval by local water authority

- Low odour

- Low sulphur and halogen content according to DIN EN ISO 3452-2 and ASME Code, Section V, Article 6

- Usable in a temperature range from +10 °C to +50 °C

- Type-tested according to DIN EN ISO 3452-2

Suitable cleaners

Suitable developers

Packages

- 1 l bottle (order no.: 9940.101)

- 5 l canister (order no.: 9940.102)

- 10 l canister (order no.: 9940.103)

- 25 l canister (order no.: 9940.125)

- Barrel and IBC on request

KD-CHECK FP-WB-2

- Fluorescent water-based penetrant

- Sensitivity class 2

- Water- and solvent-washable

- Suitable for metals and non-metals (suitability must be checked beforehand)

- Reduced test agent consumption due to low viscosity and optimal dripping properties

- Very good wetting properties

- Low background due to very good wash-off properties even on rough surfaces

- High test reliability due to strong contrast formation

- Very good biodegradability according to EN ISO 9888

- Dischargeable in aqueous dilution after approval by local water authority

- Low odour

- Low sulphur and halogen content according to DIN EN ISO 3452-2 and ASME Code, Section V, Article 6

- Usable in a temperature range from +10 °C to +50 °C

- Type-tested according to DIN EN ISO 3452-2

Suitable cleaners

Suitable developers

Packages

- 1 l bottle (order no.: 9940.201)

- 5 l canister (order no.: 9940.202)

- 10 l canister (order no.: 9940.203)

- 25 l canister (order no.: 9940.225)

- Barrel and IBC on request